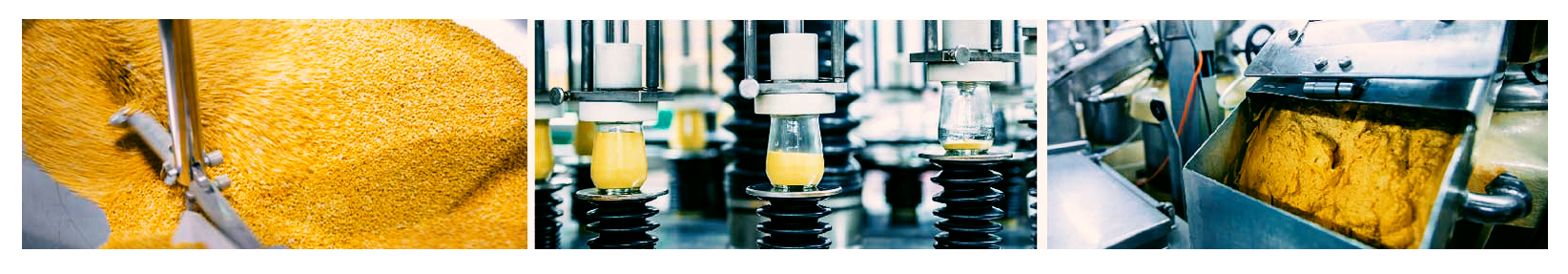

UNI DAN was established in 1998 as a grocery manufacturer. Nowadays the company is leading in the area of horseradish root processing and plays an important role on the Russian grocery market.

Today it’s a state-of-the-art establishment with its own production facilities and production lines, storage facilities, cold storage and freezer areas; with its own vehicle pool and professional management team.

Today it’s a state-of-the-art establishment with its own production facilities and production lines, storage facilities, cold storage and freezer areas; with its own vehicle pool and professional management team.